A Flexible Cutting Edge Solution

Universal Flex Steel Cutting Edge Assembly

The AdvantEDGE is the new flex steel cutting edge assembly for snow plows and pushers of all sizes. The spring-loaded sectional design creates a live edge that contours with uneven surfaces for a cleaner scrape. It also reduces noise caused by the cutting edges and prevents excessive wear to its steel or carbide edges.

Harness this new floating sectional cutting edge featuring universal mounting capability to most any snowplow or snow pusher out there. Upgrade any old plow and pusher equipped with a standard highway punch with the latest technology in flex steel cutting edges, without the need to invest in a whole new plow!

Sectional Steel or Carbide Cutting Edge Technology

Left Behind Snow | All Snow Removal Contractors Battle It. All Pedestrians Experience It. All Operators Get Frustrated With It.

Clearing snow efficiently from uneven surfaces is hard work and almost impossible when you are dealing with tight time constraints.

Protrusions, drainage ditches, crowns, peaks, and valleys all leave snow behind with standard plows. Soft rubber and plastic edges wear too quickly and cannot scrape like steel edges.

There are other snow plows designed with ‘floating sections’ with the claim to fame that they clean better, and reduce salt usage. However not a single one of these plow products hit 100% on all service, durability, price, and availability reviews. Because of the proprietary designs that make them specialized to each plow manufacturer, parts can be scarce, expensive, or you experience lack of dealer support. They can also be overpriced, and hard to get – waiting is not what your customers do, right?

KAGE AdvantEDGE Universal Sectional Cutting Edge

KAGE AdvantEDGE Universal Sectional Cutting Edge

The KAGE AdvantEDGE™ is the new type of sectional cutting edge that will revolutionize snowplow operations everywhere. Using a simple and universal design, contractors and municipalities can take advantage of a Hardox® steel or carbide cutting edge that contours automatically to uneven surfaces. This simple assembly bolts onto any moldboard or trip-edge plow and instantly gives your old plows a revolutionary sectional edge made up of 18″ and 24″ sections and offers 1.375 inches of vertical travel in each section.

The AdvantEDGE will make your job easier and save you from replacing the more expensive, dedicated sectional snowplow devices. Scrape in just one pass with KAGE’s flex steel sectional cutting edge, and improve the cleaning performance with the KAGE AdvantEDGE!

Automatically Navigates Peaks And Depressions

No pavement is perfectly flat, so unless your cutting edge adjusts to it, you’re leaving snow behind. The independent cutting edge sections of the AdvantEDGE™ help the blade to contour to the shape of any surface. The more snow you can remove during your plowing operations, the less salt and sand usage you’ll have.

Hardox® Steel Cutting Edge Sections

Hardox® Steel Cutting Edge Sections

Each 18″ or 24″ steel cutting edge section is milled from the proprietary Hardox wear-plate, common to the mining industry for abrasion resistance and strength. Compared to carbide cutting edges, Hardox is not as brittle, and does not require any additional backing plates.

- Better than AR, the 5/8” thick AdvantEDGE blades will outlast AR 2:1, and your standard 1084 High Carbon edges 4:1.

Carbide Cutting Edge Sections

Carbide Cutting Edge Sections

Also available in 18- and 24-inch sections for the AdvantEDGE are carbide cutting edges. Carbide is when known for its long wear life and ability to maintain a sharper edge for longer. In fact, our carbide edges last twice as long as the Hardox edges.

Reduce Premature Wearing

The very nature of the AdvantEdge reduces premature wear of your cutting edges because of the even pressure across the entire edge. The edge is instantly contouring to every surface, and adjusting so that the plow is not grinding away on peaks, and wearing the center or edges faster than the rest.

- Independent and consistent pressure across the cutting edge creates consistent wear across the blade.

- Limits replacement needs due to crowning and gutter wear.

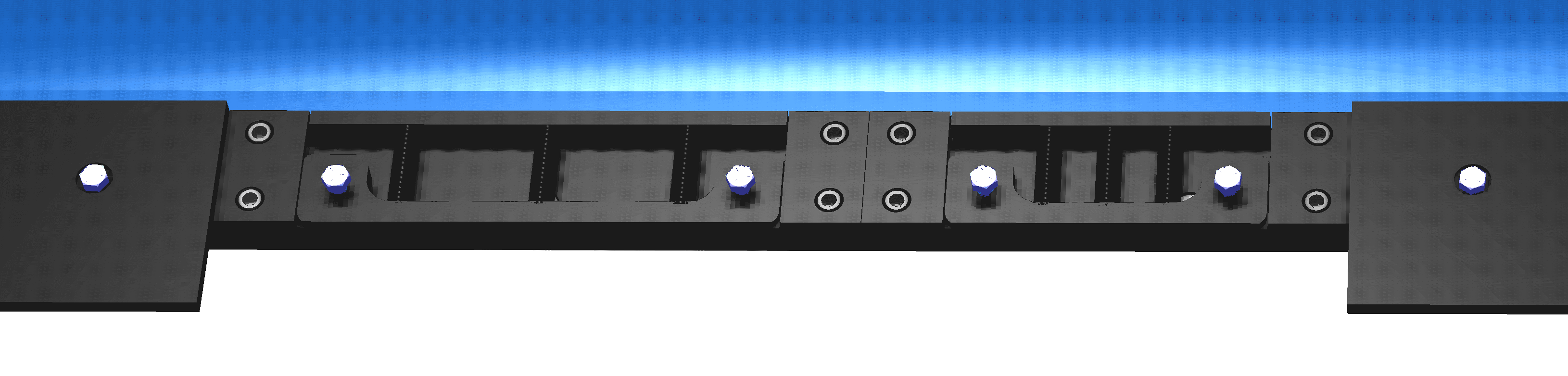

Pressure Adjustable Encapsulated Design

This patented design give you the flexibility to adjust the pressure on each section, so that whatever the weight of the plow, you can obtain just the right amount of preload.

This patented design give you the flexibility to adjust the pressure on each section, so that whatever the weight of the plow, you can obtain just the right amount of preload.

Each section of the AdvantEdge is equipped with multiple 120 lb/inch die springs. You will use a simple calculation to determine just the right quantity of springs for your particular plow weight and width.

The AdvantEdge uses a closed-face design, reducing the impact that salt, sand, and ice can have. Each section is completely covered by the cutting edge, which is easily replaced by removing two bolts.

If you ever need internal access to replace or add springs, simply remove the cutting edge.

American Made Patented Design

Not only is KAGE Innovation revolutionizing the snow removal industry, but it is manufacturing its innovations at a high quality and process standard that you would expect from an American manufacturing company.

All of the sliding components of the AdvantEDGE are milled out of 1045 steel and case hardened for abrasion, corrosion, and lubricity. The final assembly is then completely assembled in the U.S. and shipped, ready to install on your new or existing plow! All mounting hardware necessary for installation is included.

Reduces Damage To Plowed Surfaces

Large pit on asphalting highway. Your operators try to clean the lots their best – and sometimes in an effort to clean “down to blacktop” they will just push harder. This operator enthusiasm doesn’t do much for removing the snow, but the asphalt, concrete, and other embeds feel the extra pressure of that steel as it grinds everything down.

The AdvantEDGE reduces the damage to curbs, asphalt/concrete transitions all while scraping better! It’s truly a win/win for you and your customers.

How much weight does the AdvantEDGE system add to my plow?

How much weight does the AdvantEDGE system add to my plow?

With all that goes into this universal contouring cutting edge system, you might think it is quite heavy, but in reality, the AdvantEDGE components add just 22.14 pounds per foot to your existing plow – not including the cutting edges that you’d already have in place. To get a better idea here’s quick guide to plan for the additional weight based on the length of your plow.

Additional AdvantEDGE Weight

- 8 ft plow – 177.12 lbs

- 10 ft plow – 221.40 lbs

- 12 ft plow – 265.68 lbs

- 14 ft plow – 309.96 lbs

- 16 ft plow – 354.24 lbs

- 18 ft plow – 398.52 lbs

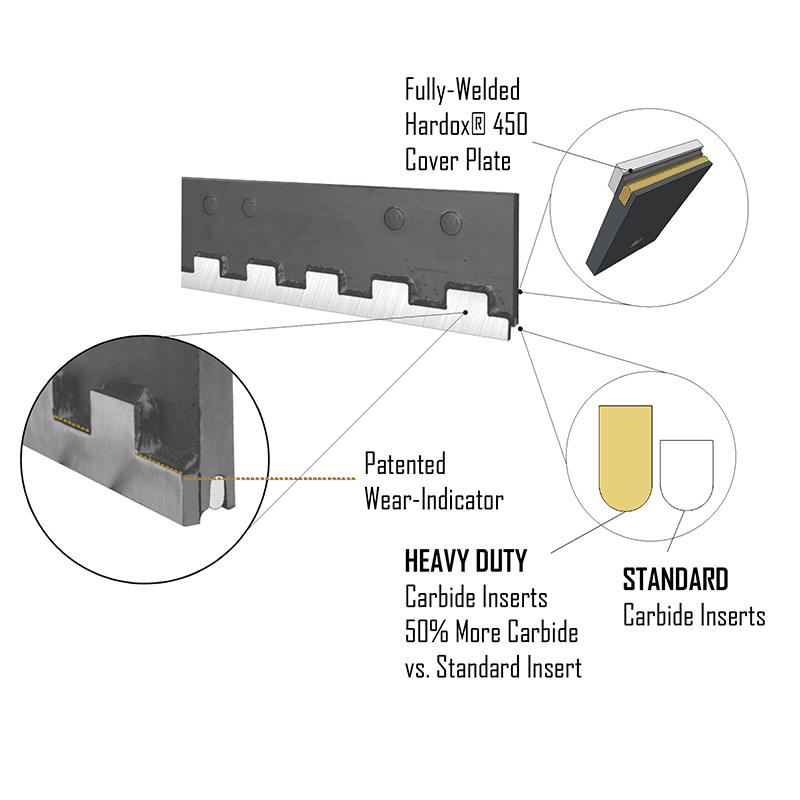

Carbide Cutting Edge Sections

Available in 18- and 24-inch sections for the AdvantEDGE are carbide cutting edges. Carbide is when known for its long wear life and ability to maintain a sharper edge for longer. In fact, our carbide edges last twice as long as the Hardox edges.

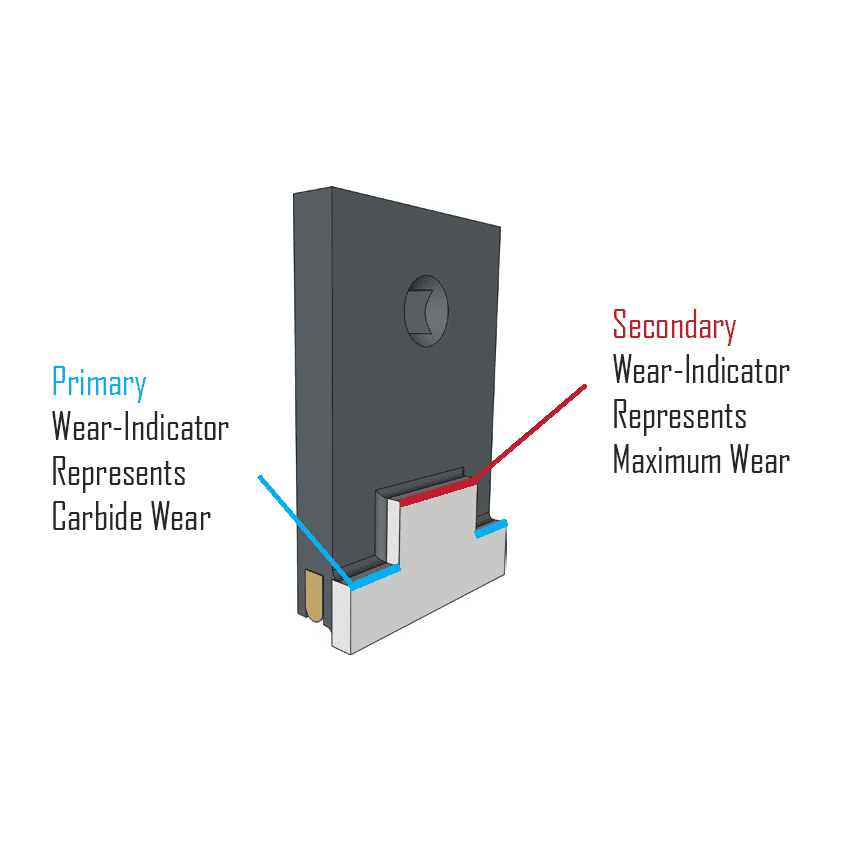

The carbide inserts are protected by a fully-welded Hardox cover plate to prevent chipping. And feature two highly-visible wear indicators to let you know when it’s time to replace the cutting edges.

Hardox® Steel Cutting Edge Sections

Each 18″ or 24″ steel cutting edge section is milled from the proprietary Hardox wear-plate, common to the mining industry for abrasion resistance and strength. Compared to carbide cutting edges, Hardox is not as brittle, and does not require any additional backing plates.

- Better than Abrasion Resistant (AR) steel, the 5/8” thick AdvantEDGE blades will outlast AR 2:1, and your standard 1084 High Carbon edges 4:1.

Overview

Overview

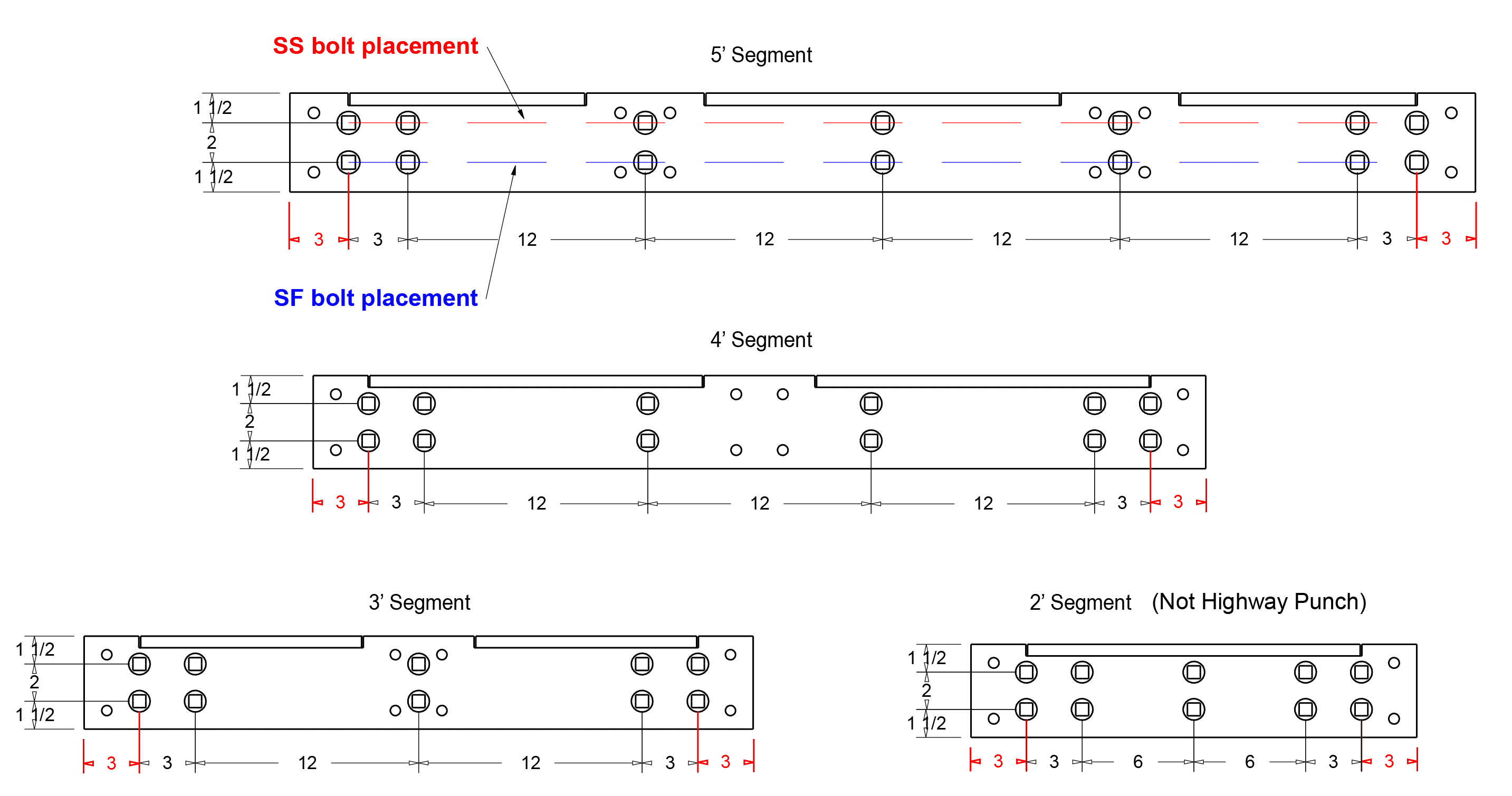

Each Kit is comprised of various Segment lengths to achieve the proper combined length of the overall plow. Each Segment comprises the nominal size Backing Plate, and Cutting Edge Sections + Hardware. Cutting Edge Sections and Hardware are then bolted to the Backing Plate. All Backing Plates have several different bolt patterns built in to allow ‘universal’ mounting to almost any plow or pusher. The Backing Plates also feature two rows of bolt hole options to allow for different mounting heights. Choose from 2, 3, 4, and 5 foot Segments, or order as one complete Kit. Ordering is easy, and any standard length of plow, trip edge and trip moldboard type can be accommodated.

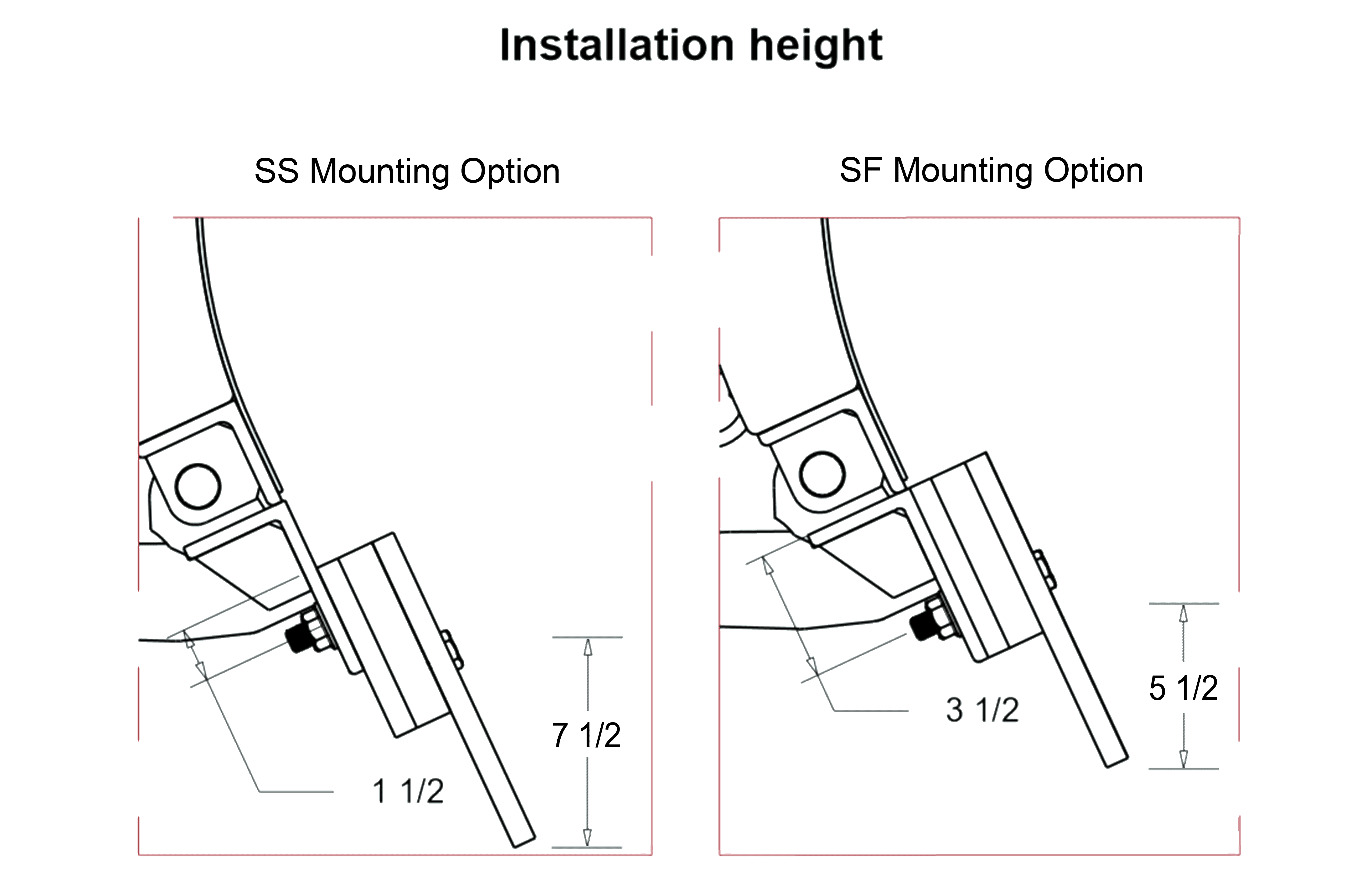

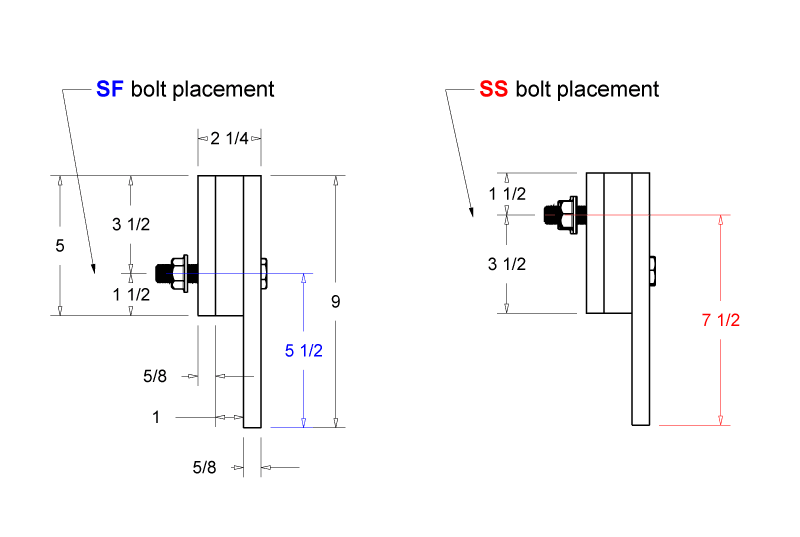

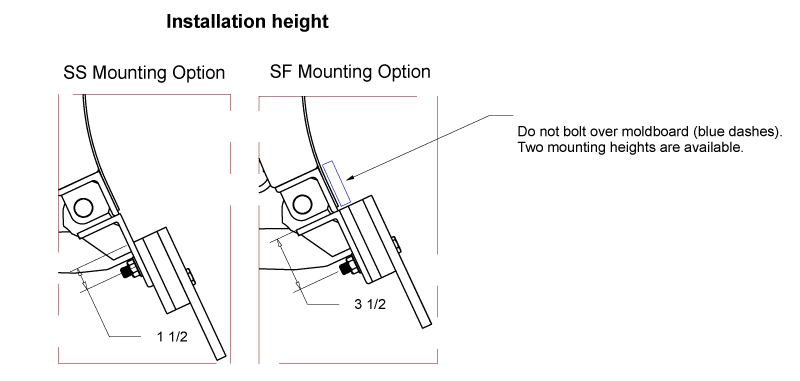

Mounting Heights

SS and SF represent the two different mounting heights for the backing plates. SS has 1.5″ Stick Up, and SF has 3.5″ Stick Up. Every backing plate has both options, it’s simply a matter of how you bolt it up!

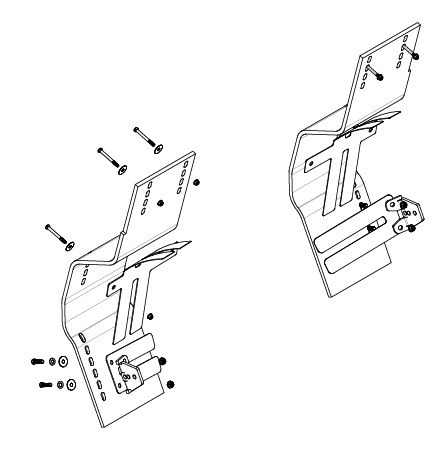

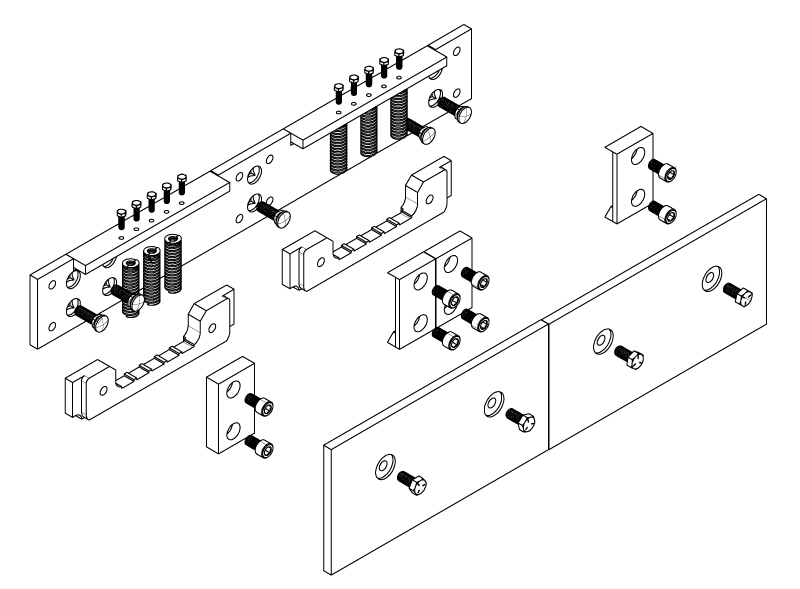

Segment Build

Each Segment is made up of the nominal size Backing Plate, and 1 or more Cutting Edges and Sectional Hardware pictured below.

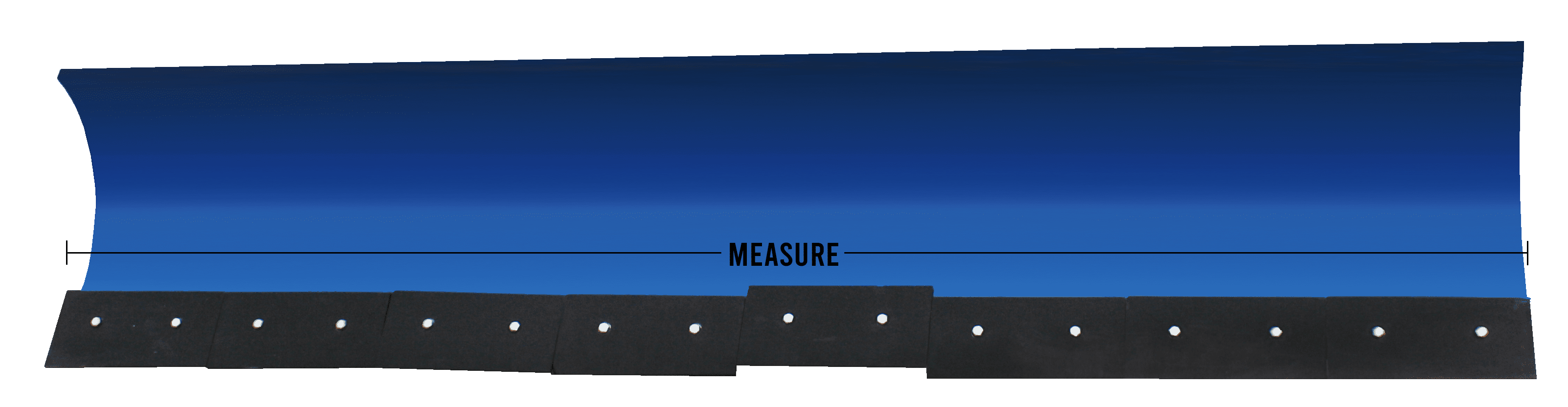

Order By Complete Kit

You can order the AdvantEdge by the kit. A kit will come with all of the Segments necessary for your particular plow. Simply determine the overall length of your blade, and if you have a split trip edge. Once you have that information, you are ready to order!

- It is necessary to have standard highway punch, OR 12″ O.C. bolt spacing.

- If your plow has a split trip edge, you should order your new AdvantEDGE by segment rather than a complete Kit.

- Determine that your plow has adequate Stick Up clearance so that the Backing Plate does not interfere with your moldboard.

- Common Kit sizes range from 8′ (comes with two 4′ Segments), 10′ (comes with two 5′ Segments), 14′ (comes with two 5′ segments and one 4′ segment). Many other kit configurations are available!

Order By Segment

You can order your new AdvantEDGE by adding individual Segments (Backing Plates) together to achieve your desired length. Order by Segment when your plow has a split trip edge. Determine the overall length of each trip edge section if your plow has a split trip edge. With that information you’re ready to order!

- It is necessary to have standard highway punch, or 12″ O.C. bolt spacing.

- Determine that your plow has adequate Stick Up clearance so that the Backing Plate does not interfere with your moldboard.

- Choose between 2′, 3′, 4′, and 5′ segments to obtain the desired overall length.

Front And Wing Blade Flex Edge System

Until now, sectional plows and cutting edges have only been available on a few brands of plows. The AdvantEDGE makes it possible to harness sectional cutting edge technology on almost any plow or pusher available on the market today. That includes, city, town, county, and state highway truck plows!

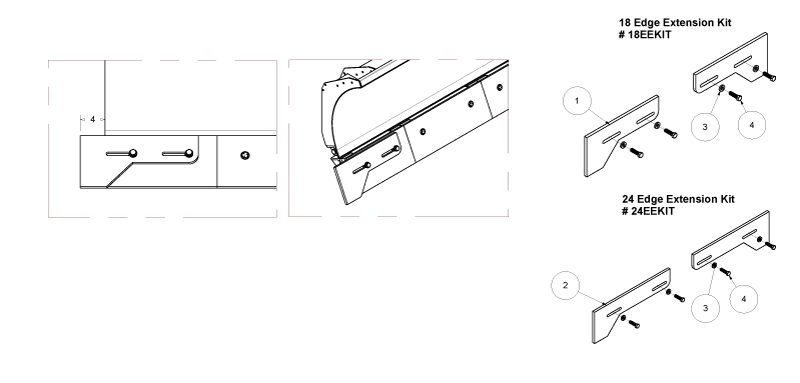

Extenders

Optional Extenders can bridge the gap of fraction sizes, or between the end plates of your pusher.

KAGE Snow Catch Upgrade

KAGE SnowFire plow systems being upfitted with an AdvantEDGE will require an upgraded Snow Catch Kit shown below. PART# SCAE-K

Sectional cutting edges are changing the way snow fighters do business. Their ability to contour to uneven surfaces not only increase efficiency but also comfort and safety. This buyers guide will answer many frequently asked questions about live, flex and floating cutting edges. Check out the blogs below to get in depth knowledge about the innovative cutting edges and how the AdvantEDGE fits into the mix.

Choosing the Right Snow Plow Cutting Edge Material

Jan. 8, 2024 – This blog serves a guide to choosing the right cutting edge for different locations and snow or ice conditions. This includes when to use Hardox Steel or Carbide sectioned AdvantEDGE cutting edges. It also weighs the pros and cons of other steel, carbide, poly and rubber cutting edges.

Jan. 8, 2024 – This blog serves a guide to choosing the right cutting edge for different locations and snow or ice conditions. This includes when to use Hardox Steel or Carbide sectioned AdvantEDGE cutting edges. It also weighs the pros and cons of other steel, carbide, poly and rubber cutting edges.

What is a flex edge snow plow?

Nov. 10, 2023 – Discover what makes a flex edge snow plow unique, including the materials and technology used to make this type of a plow work. You’ll learn the pros and cons of each type of flex edge and what options are available from KAGE.

Nov. 10, 2023 – Discover what makes a flex edge snow plow unique, including the materials and technology used to make this type of a plow work. You’ll learn the pros and cons of each type of flex edge and what options are available from KAGE.