If you’ve spent any amount of time operating a snow plow, you know that the cutting edge is where the work really happens. This is the part of the plow that scrapes against the pavement, removing snow and ice from the surface. Over time, no matter how durable it is, the cutting edge wears down and needs replacement. That’s where aftermarket snow plow cutting edges come into play.

An aftermarket snow plow cutting edge is a replacement edge not necessarily purchased from the original manufacturer of the plow, but instead from a third-party source. These products are designed to fit a wide variety of plow models and brands, giving operators flexibility in both materials and cost. In many cases, aftermarket cutting edges can match—or even exceed—the quality of the factory-installed part.

The Role of the Cutting Edge

Before diving into the aftermarket options, let’s recap why the cutting edge is so important. The cutting edge:

-

Scrapes the Surface – It’s the component that comes into direct contact with pavement, ice, and snow.

-

Protects the Moldboard – Without a cutting edge, the moldboard (the large, curved blade) would be damaged far more quickly.

-

Determines Clearing Performance – The design, material, and condition of the cutting edge directly impact plowing effectiveness and efficiency.

Because of the heavy wear and tear involved in plowing, cutting edges are a consumable component. They’re expected to wear down over time, much like tires or brake pads.

What Makes an Edge “Aftermarket”?

The key distinction between an OEM (Original Equipment Manufacturer) cutting edge and an aftermarket snow plow cutting edge is the source. OEM edges come directly from the company that made your plow. Aftermarket cutting edges come from a different manufacturer but are designed to fit your plow’s mounting pattern and specifications.

For many plow operators, aftermarket options are appealing because they can:

-

Offer different material choices tailored to specific conditions.

-

Sometimes reduce cost without sacrificing durability.

-

Be easier to source during peak snow season.

-

Allow customization for unique job site demands.

Universal Bolt Patterns – The Key to Interchangeability

Universal Bolt Patterns – The Key to Interchangeability

One potential challenge when buying aftermarket snow plow cutting edges is bolt pattern compatibility. The bolt pattern refers to the arrangement of mounting holes used to attach the edge to the plow.

This is where KAGE Innovation stands out. KAGE designs its snow plow cutting edges with a universal bolt pattern—also known as the highway punch or DOT punch pattern. This is the same style used by many municipalities, DOT crews, and large snow removal contractors.

The benefit? If you own a KAGE plow, you aren’t locked into proprietary edges. You can purchase replacement cutting edges from any supplier that offers this standard pattern. That means you’re never stuck waiting for a manufacturer-specific shipment when snow is piling up and your cutting edge is worn out.

Cutting Edge Materials – Matching the Edge to the Job

KAGE Innovation offers several different materials for its plow cutting edges, all with the universal bolt pattern – meaning although KAGE manufactures plows, it’s cutting edges also serve as aftermarket cutting edges for other brands of plows that utilize a DOT punch:

1. High Carbon Steel

A classic, cost-effective option for general-purpose snow removal. High carbon steel edges are tough, capable of cutting through packed snow and ice, and can handle rugged conditions. They wear down faster than some specialty materials but are inexpensive to replace.

2. Polyurethane

Poly edges are ideal for protecting delicate surfaces like decorative concrete, parking decks, or paver driveways. They’re quieter, reduce vibration, and help prevent surface scratching and rust marks. While they don’t scrape ice as aggressively as steel, they’re perfect for sites where surface preservation matters.

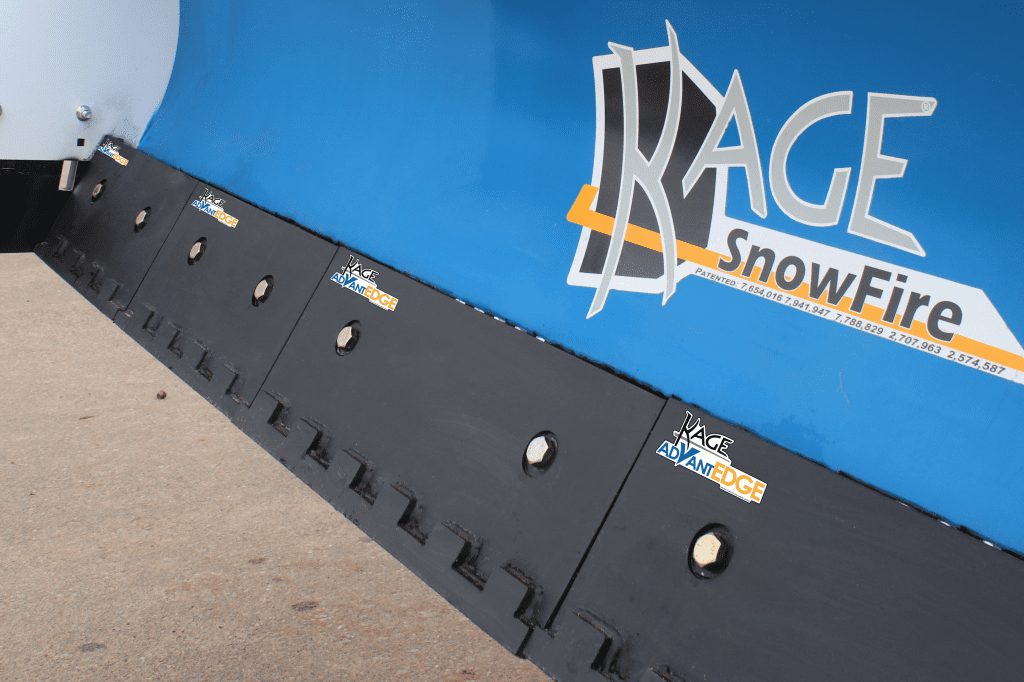

3. Hardox Steel (AdvantEDGE Sectional Cutting Edge)

Hardox steel is a wear-resistant alloy that’s far more durable than standard carbon steel. KAGE uses Hardox in its AdvantEDGE sectional cutting edges for operators who want the durability of steel with extended lifespan, especially in high-abrasion environments. With the spring loaded sections of the AdvantEDGE system, these Hardox cutting edge last even longer as they do not have to endure uneven or excessive down pressure.

4. Carbide (AdvantEDGE Sectional Cutting Edge)

Carbide edges are the gold standard for longevity. By embedding carbide inserts into a steel base, these edges resist wear far longer than standard steel – and Hardox. They’re especially useful for contractors who log high annual plowing hours – and/or run heavier machines – and want to minimize downtime for replacements. AdvantEDGE cutting edge systems with Carbide sections are the top-level aftermarket snow plow cutting edges for everything from scraping ability to lifespan.

Comparison Chart – KAGE Cutting Edge Materials

| Material | Durability | Surface Protection | Scraping Power | Cost | Best For |

|---|---|---|---|---|---|

| High Carbon Steel | Medium | Low | High | $ | Everyday plowing, general use, cost-conscious operations |

| Polyurethane | Medium-Low | High | Medium-Low | $$ | Delicate surfaces, low-noise requirements, parking ramps |

| Hardox Steel | High | Low | High | $$$ | High-abrasion conditions, long-life steel option |

| Carbide | Very High | Low | Very High | $$$$ | Heavy commercial use, minimal downtime, extreme durability |

Why KAGE’s Approach to Cutting Edges is Different

While KAGE Innovation includes a cutting edge with every plow sold, it doesn’t lock customers into buying replacements exclusively from KAGE. That’s a deliberate choice.

By using a universal bolt pattern, KAGE:

-

Empowers contractors to shop for the best price and material option.

-

Reduces downtime because operators can source replacements locally.

-

Supports versatility—contractors can swap between poly, steel, Hardox, or carbide edges depending on the job.

In contrast, some plow manufacturers design their edges with proprietary mounting patterns, effectively forcing customers to buy replacements only from them—often at higher prices and with longer lead times. KAGE’s open compatibility approach is a contractor-friendly alternative.

When to Replace Your Cutting Edge

Even the toughest cutting edge will eventually wear down. A good rule of thumb is to replace it before the wear reaches the mounting bolts. Operating with an overly worn edge risks damaging the moldboard, which is a far more expensive repair.

Signs it’s time for a replacement:

-

The edge has worn down to within ½ inch of the bolt holes.

-

The plow is leaving behind more snow than usual.

-

You notice uneven wear patterns that affect scraping performance.

- In the case of the Carbide sections of the AdvantEDGE, the castle like design of the carbide also offers good wear indicators. When you were through the bottom of the “castle” it’s time to order your next set of cutting edges, but there is still life in them. Once you’ve worn through the “castle peaks” it’s time to replace the cutting edges.

The Bottom Line

An aftermarket snow plow cutting edge gives contractors and operators flexibility, choice, and potentially cost savings without sacrificing performance. Whether you prefer the ruggedness of high carbon steel, the surface protection of polyurethane, the durability of Hardox, or the extreme longevity of carbide, there’s an aftermarket option to fit your needs.

KAGE Innovation’s commitment to universal bolt patterns means its plow owners are never tied down to a single supplier. This open compatibility is a big advantage in an industry where downtime costs money and snow waits for no one.

In short, know your bolt pattern, choose the right material for your conditions, and don’t be afraid to explore aftermarket options. With the right cutting edge, your plow will keep performing season after season.

Recent Comments