When you’re buying or running snow removal and land-grading equipment, the small details matter — and few things matter more than the cutting edge. KAGE Innovation fits bolt-on cutting edges to every SnowFire, SnowStorm, SnowDozer and ShadowBlade snow plow and to the GreatER Bar land plane for a reason: they give operators real, practical benefits on the job every day. Below I’ll walk through the advantages of bolt-on edges, why they outperform welded alternatives in many situations, how they protect your machine and your bottom line, and best practices for selection and maintenance.

1. Fast, simple, and inexpensive replacement — less downtime, lower cost

One of the most obvious benefits of bolt-on edges is serviceability. When a cutting edge wears down, gets nicked, or is damaged by a hidden piece of debris, you don’t have to send the whole blade out for costly repair or replace an entire moldboard. With bolt-ons you:

-

Swap the worn edge for a new one in minutes instead of hours.

-

Save on labor and shop time — a field replacement can often be done between jobs.

-

Keep machines working during peak season when downtime is most expensive.

For contractors and municipalities who can’t afford long outages during storms or grading windows, this is a game changer.

2. Versatility — pick the right edge for the job

Bolt-on systems let you tailor the plow or land plane to the surface and task at hand:

-

High-carbon or AR steel bolt-on edges are great for heavy-duty scraping of hard surfaces like asphalt and compacted gravel.

-

Tungsten carbide or carbide-tipped edges are ideal where extreme abrasion is common (for example, lots of salt, ice melt, or frozen aggregate).

-

Polyurethane / composite edges reduce damage on delicate surfaces (pavers, tiles, decorative concrete) and lower noise and vibration.

Because KAGE fits bolt-on cutting edges across its Snow Plow and Pusher families as well as its GreatER Bar, operators can change edge types quickly to move between jobs — sidewalks to parking lots to gravel roads — without needing different plows.

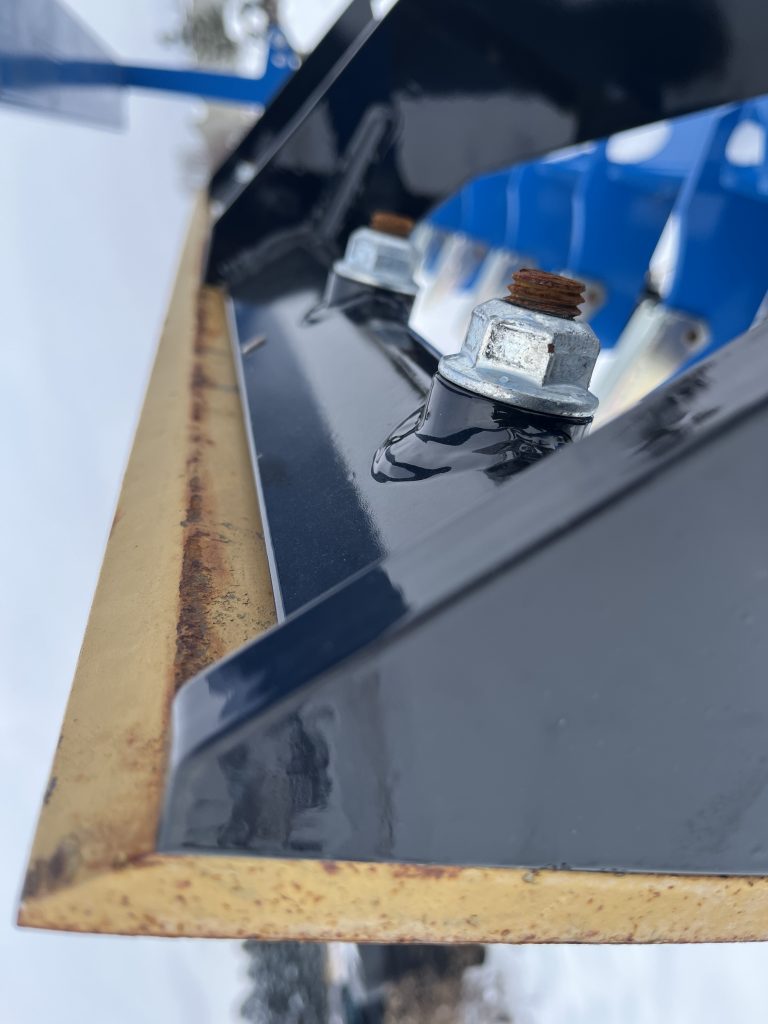

3. Protects the moldboard and structural components

A cutting edge is sacrificial by design. It takes the wear, abrasion, and impacts so the moldboard and welds don’t have to. Bolt-on edges keep:

-

The moldboard in original condition (less corrosion and wear).

-

Mounting points and welds free from repeated grinding and repair.

-

Resale value higher, because the primary structure remains intact.

Replacing a bolt-on edge routinely is far cheaper and less invasive than repairing a worn, pitted moldboard.

4. Improved scraping performance and longevity

4. Improved scraping performance and longevity

Bolt-on edges allow for consistent edge geometry and a clean, replaceable contact surface. That consistency yields:

-

Better, more even scraping across the full width of the blade or land plane. KAGE even took this bolt-on benefit to the next level with its AdvantEDGE contouring snow plow cutting edge. Not only does the cutting edge system bolt on to the plow, but each section of cutting edge bolts on separately for easy replacement of only the worn sections.

-

Predictable wear patterns that are easy to manage (so one area won’t fail unexpectedly).

-

The option to flip reversible bolt-on edges to double service life — literally two usable cutting surfaces per part.

For land-grading and finish work, the ability to keep a sharp, dependable edge improves finish quality and reduces passes.

5. Safer, less damaging operation

5. Safer, less damaging operation

Welded edges that become thin or brittle can fail catastrophically. Bolt-on edges tend to warn you before they completely fail: you’ll see wear and can plan replacement. That predictability:

-

Reduces the chance of sudden breakage that could fling debris or damage attachments.

-

Lowers risk of unexpected failure during a busy shift, which protects both equipment and operators.

-

Helps maintain proper blade angle and vibration characteristics, improving operator control.

6. Easier inventory management and predictable budgeting

Bolt-on edges are standard parts you can stock, count, and order in bulk. For fleet managers this means:

-

Predictable replacement cycles and budget planning.

-

Fewer unique repair orders to manage — one size of bolt pattern can often work across multiple machines or blade widths.

-

The ability to keep spares on hand and swap them in the field.

For seasonal businesses, having a shelf of spare bolt-on cutting edges is a small investment that prevents revenue-crushing downtime.

7. Better for resale and long-term asset value

Equipment that’s been maintained with replaceable sacrificial edges tends to look and perform better over time. A well-cared-for KAGE plow or GreatER Bar with intact moldboard, fresh hardware, and a recently replaced cutting edge fetches a better price on trade-in or resale than a unit with welded, patched, or permanently altered edges.

8. Environmental and surface-care benefits

Choosing the right bolt-on material (for example, poly edge on decorative concrete) protects the surface being worked on and reduces the need for corrective repairs later. Less surface damage means:

-

Lower costs for property owners (fewer paver replacements, less concrete repair).

-

Less waste and a smaller environmental footprint over the life of the work.

9. Clear maintenance routine — extends total life of attachment

Bolt-on systems make preventive maintenance straightforward:

-

Inspect edges and bolts daily in heavy use, or weekly in lighter use.

-

Torque check the hardware after the first few hours of service post-installation.

-

Flip reversible edges when one side reaches wear limits.

-

Keep a small toolkit and spare bolts in the truck for quick swaps.

These predictable steps extend the life of the plow or GreatER Bar and keep performance consistent throughout the season.

Bolt-On vs Welded — quick comparison

-

Replaceability: Bolt-on — excellent. Welded — poor.

-

Upfront cost: Bolt-on slightly higher initially (for hardware), but much lower lifecycle cost. Welded may be cheaper upfront but costly to repair.

-

Versatility: Bolt-on allows edge type swaps; welded does not.

-

Downtime: Bolt-on minimizes it. Welded increases risk of extended shop time.

-

Surface friendliness: Bolt-on gives option for poly/composite when needed.

Choosing the right bolt-on edge for your KAGE plow or GreatER Bar

Choosing the right bolt-on edge for your KAGE plow or GreatER Bar

-

Assess surface type (asphalt, concrete, gravel, pavers).

-

Consider abrasion level (salt, grit, frozen aggregate).

-

Match material: high carbon steel/AR for heavy scrape, Hardox or carbide for extreme abrasion, poly for delicate surfaces.

-

Keep spare bolt kits and a torque wrench for correct installation.

Bolt-on cutting edges are a small design choice that delivers outsized returns: less downtime, lower repair cost, better surface results, and simpler maintenance. That’s why KAGE Innovation uses bolt-on edges across its snow plows, snow pushers and the GreatER Bar land plane — it gives operators the flexibility and durability they need to get more work done, more reliably, season after season.

Recent Comments