It’s inevitable. Snow plows will come in contact with curbs. But that doesn’t mean extensive and expensive curb damage needs to be inevitable as a result of that contact. Plowing snow can damage curbs in a variety of ways ranging from chips, cracks, gouges, scrapes and gradual erosion to rust marks. Most of that damage can be significantly reduced, if not eliminated by using proper planning, techniques and equipment.

Below you’ll see the best ways to keep your curbs in the best condition possible throughout the snow removal season.

- Snow Stakes

- Poly Skids

- Poly Cutting Edges

- Trip Edges

- Floating Skids

Snow Stakes

The best prevention for anything is to avoid it all together. That’s where snow stakes come into play. By design, snow stakes alert plow operators as to the location of the curb so they can take precautions to avoid contact and/or approach with caution. This will protect the both the curb and the plow from hard impact – the cause of most chips, cracks and gouges. It’s hard to cause curb damage without contact!

Poly Skids

Steel plow materials are designed to be hard in order to provide the best scrape for ice and hard-packed snow. However, the skids and shoes on the plows do not need to scrape. In fact, their purpose is exactly the opposite – to prevent damage to more sensitive surfaces such as vegetation and… You guessed it! Curbs!

You might think that something hard like steel, is necessary to withstand the abuse and abrasion endured from sliding across paved surfaces. That’s simply not the case. In fact it often results in more machine, plow and curb damage.

As you rub a steel plow skid against a curb, it not only wears away at the curb, but it also leaves residue from the plow on the curb. Any material containing iron is subject to rusting, so that steel residue, which has now been ground into your curb eventually oxidates and rust, leaving those unintentional reddish “racing stripes” on the curbs.

Polyurethane skids, on the other hand, often wear just as well as steel but do not contain iron and will not rust. They also are much gentler on the curbs, preventing that erosion that is enhanced by friction with steel. Plus, if you run into a curb with a poly skid, it will absorb, flex and disperse much of that impact within the skid where steel shoes, if they give at all will bend and damage your plow. If they don’t give, that force is either taken on by the curb and transferred back into your machine/hydraulics, causing significant damage and endangering the safety of the who continues to move forward toward the windshield when the machine comes to an abrupt stop.

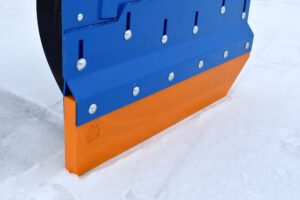

Poly Cutting Edges

For many of the same reasons poly skids reduce damage to curbs, so do poly cutting edges. The difference is that the cutting edges don’t tend to come in contact with curbs as often as the skids, unless someone is plowing perpendicular to the curb and pushing snow overtop of and back from it. Poly cutting edges will still scrape snow very well but are much gentler on the substrate and obstacles – including curbs.

Trip Edges

Much like the flexibility of polyurethane serves as a safer way to divert the force of impact, so do snow plow trip edges. Think of it much a breakaway basketball hoop. The rim “breaks away” with the use of springs in order to take the pressure off of the back board and prevent the back board from shattering or the rim supports from pulling through it.

Snow plow trip edges serve that same purpose, protecting both the plow from tearing away from its supports and significantly reducing the force of impact against the curb – therefore reducing the risk of curb damage. If fact, it even allows the plow cutting edge to glide up and over the curb as the cutting edge folds back, clearing snow the whole time as the springs allow it to maintain and appropriate amount of pressure with the curb.

Floating Skids

While a trip edge folds backward to reduce impact force, floating skids travel vertically to accomplish the same thing. When the skid pushes against the curb, it lifts, allowing the cutting edge to continue to scrape up to the curb, while the side panels of a pusher box continue to travel over the curb, avoiding the blunt force that often causes curb damage.

Whether you’re a seasoned professional or an ambitious newbie in the snow removal business, accidents happen; operators get tired; whiteout conditions arise, and inadvertent collisions take place with curbs. Wouldn’t you want to be prepared with the right tools to make sure those incidents don’t result in costly damages and lost contracts?

Taking advantage of these 5 features can keep you on the right path to successful and profitable snow removal! Call KAGE and speak with a knowledgeable representative to make sure you maximize your curb safety features on your plow today!

Recent Comments