When you hear someone talking about carbide snow plow blades, he/she is likely referring to a carbide plow cutting edge. The “plow blade” generally refers to the moldboard while the “plow cutting edge” attaches to the bottom of the blade as is the part of the plow that actually makes contact with the ground and scrapes the snow.

Carbide as become a popular material for plow cutting edges because it traditionally last up to 20 times longer than high carbon steel cutting edges and twice as long as Hardox steel cutting edges.

Carbide cutting edges for snow plows come in multiple forms including:

- Full length steel cutting edges with carbide inserts

- Sectional steel cutting edges with carbide inserts

- Small steel cutting edge life extenders with carbide inserts

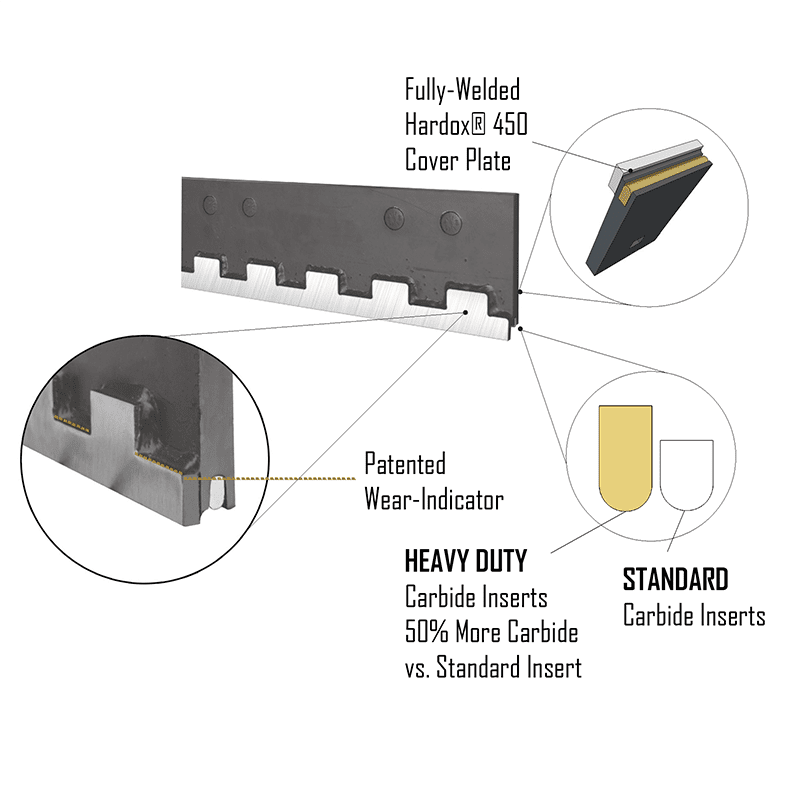

You may have noticed all three options use the word “inserts.” This is because carbide by itself, while very hard wearing, is also brittle. For that reason, the carbide material is covered by a protective steel cover plate to prevent it from chipping or shattering. Although carbide makes up a small percentage of the cutting edge itself, the presence of this popular and long lasting material in the cutting edges often leads any carbide inserted cutting edge to be simply called a “carbide snow plow cutting edge.”

Full Length Carbide Plow Cutting Edges

A full-length carbide plow edge is exactly as it sounds. The cutting edge is one piece that runs the full length of the blade. Full length cutting edges are the oldest style of snow plow cutting edge as they are simple and easiest to manufacture. There are, however, drawbacks to this type of cutting edge and it offers now flex or contouring ability and is most likely to leave snow or ice behind as most surfaces are not completely level.

Carbide cutting edges are also very heavy, so the longer the blade, the harder it becomes to install, simply due to its weight.

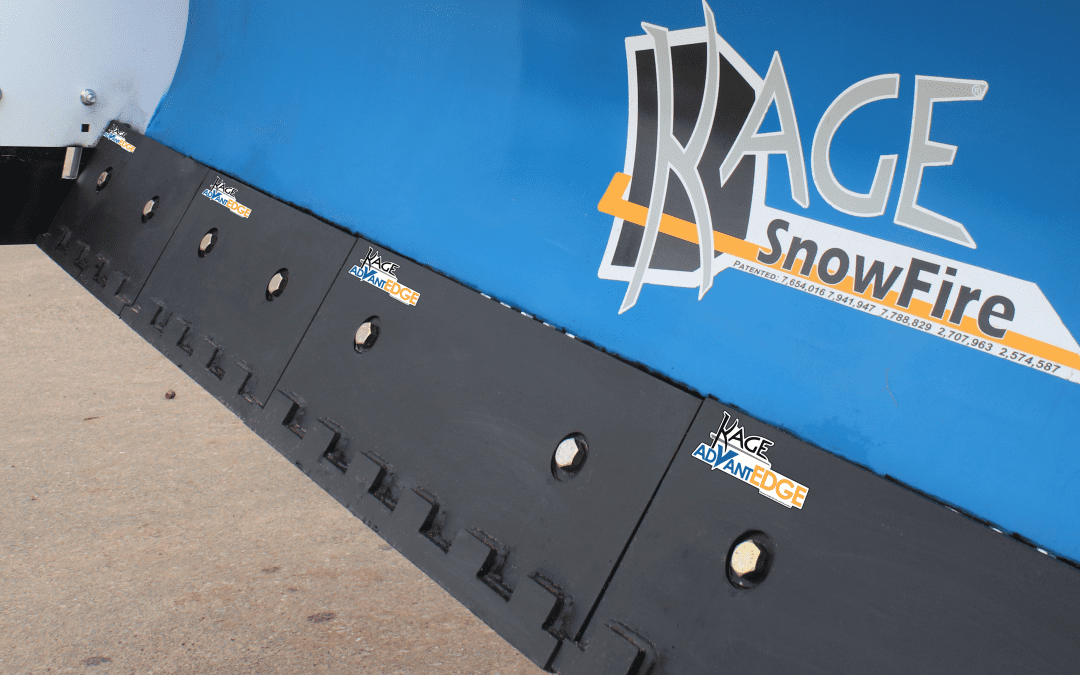

Sectional Carbide Snow Plow Cutting Edges

The word “sectional” simply means that the cutting edges are designed to be used as a series of shorter length cutting edges mounted adjacent to each other until you have enough to cover the bottom of your plow blade.

Kage’s sectional carbide cutting edges are part of its AdvantEdge floating cutting edge system. Each carbide inserted cutting edge section is either 18- or 24-inches long and is spring loaded to allow the sections to work independently to contour to uneven surfaces and road irregularities such as wheel depressions, crowns, bumps and potholes. These sections are designed to accommodate any length up to 20 feet. Each carbide inserted section weighs either 29.4 or 54 pounds.

This type of cutting edge is known to greatly reduce the amount of salt needed, due to its exceptional scraping abilities. It also prevents uneven wear of the cutting edges and reduces the amount of noise transferred back to the cab of the machine.

Snow Plow Carbide Cutting Edge Life Extenders

Since carbide cutting edges are some of the most expensive options for snow plows, many operators choose to use carbide life extenders. These are simply extra small sections of carbide inserted cutting edges that are mounted to existing cutting edges of softer material – generally near the outside edges of the blade. In the case of extra long plows, with split cutting edges, the carbide life extenders would also be placed where two cutting edges butt up to each other along the blade.

KAGE Innovation’s carbide life extenders are known as Centurion kits, which include the nuts and bolts necessary for installation. These life extenders are 9 inches long and are available in heights of 6 or 8 inches. They also weigh 15 or 20 pounds per section, respectively.

If you’re looking to get the longest possible lifespan out of your snow plow cutting edge, you’ll definitely want to consider using a carbide-inserted option.

Recent Comments