What is the Purpose of a Box Blade and a Land Plane?

A box blade leveler and a land plane attachment are both types of earthmoving equipment that are commonly used for land preparation and grading tasks. Typically designed for skid steers and tractors, both attachments are used to level landscape projects, fields, driveways, construction foundations, and gravel roads. They break up small mounds to fill in depressions. Box blades and grader bars are used for fine-tune work. Landscapers and construction workers will use a bucket to fill in large depressions or break up large hills and then go back over the area with a box blade or grader bar to perfect the surface.

What is a Box Blade?

Steel Construction

Box blades are typically constructed from high-quality steel to ensure durability and strength. They have a box like shape with a cutting edge on the bottom of it and possibly ripper teeth in front of the blade.

Multiple Blades or Teeth

Most box blades have multiple blades or teeth mounted on the bottom of the frame in front of the box to help break up soil and create a smooth, even surface.

Adjustable Blade Height

Many box blades feature an adjustable blade height, which allows the operator to control the depth of the cut and ensure an even finish.

Compatibility with Different Equipment

Box blades are designed to attach to tractors with a three point hitch in the back.

What is a Land Plane?

Large, Wide Blade

A grader typically has multiple large, wide blades that are designed to cover a wide area and create a smooth, level surface. It does this by cutting into the ground and feathering out the excess over the top of each blade to fill in the depressions.

Teeth

Some graders have retractable teeth that help tear up hard and compacted dirt or gravel.

Adjustable Teeth and Blade Depth

Many levelers have a way to adjust the blade height, allowing the operator to control the depth of the cut and ensure an even finish. They do this by applying more pressure to the grader so that it digs further into the ground. If they are equipped with teeth, most are also adjustable, by either taking out blocks or adjusting each tooth.

Tilt Adjustments

Most graders also have the ability to tilt the blade, which allows for greater control when working on sloped surfaces. This is either done by a top link on a tractor or by the boom of a skid steer.

Compatibility

Levelers can be attached to a variety of equipment, including tractors, and skid steers, such as Bobcat, or CAT.

Durability

Graders are typically constructed from high-quality steel to ensure durability and strength and last a few seasons.

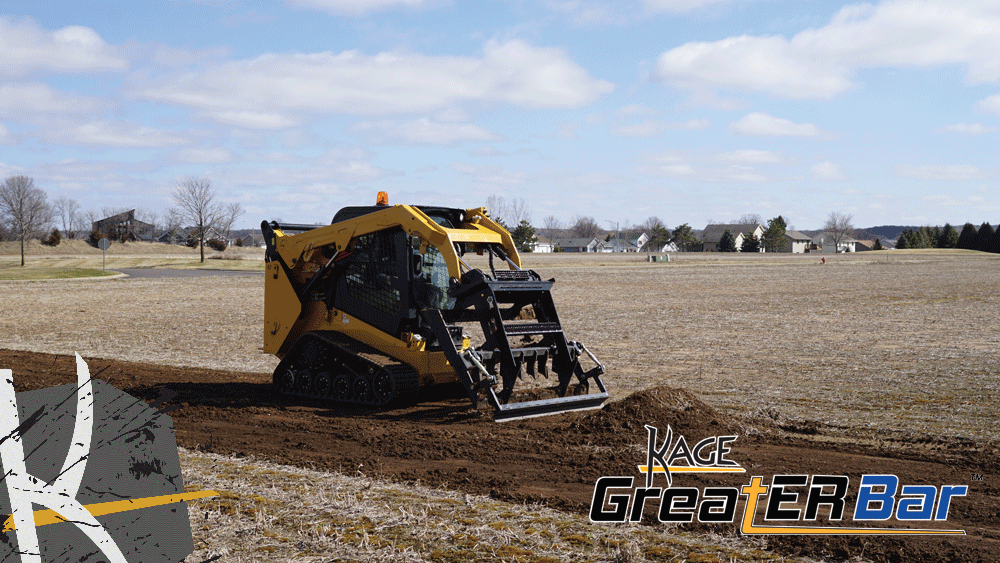

KAGE’s Unique GreatER Bar

The KAGE GreatER Bar is a land plane with mechanically activated scarifier ripper teeth. There are no hydraulics involved and the operator does not have to leave the cab. They simply press down on the foot bar with the skid steer boom and the teeth are activated. This makes switching between tasks seamless.

This grader also has extra support gussets on the frame to ensure the structural integrity of the attachment.

It has easily replaceable wear parts such as the tooth caps or cutting edges. Three dual-edged cutting edges that are just bolted on and only takes one person to replace. The scarifier tooth caps are held in place by a roll pin and pop out by a hammer and possibly a punch. These features make the maintenance of the grader fast, easy, and affordable.

Each wear item on the GreatER Bar is made out of high quality steel. The ripper teeth and latching mechanism are made of Hardox steel and the cutting edges are made of high carbon steel. This helps cut down on down time from replacing parts and extends the life of your attachment.

This driveway grader, construction grader, and landscape grader is built to make it easy for the operator. It takes out time consuming tasks such as dropping each tooth to the appropriate height every time they need to be used, or unhooking the hydraulics to switch to the bucket. It also has automatic floating teeth when the teeth are activated and the operator drives in reverse.

Recent Comments