The ideal steel thickness of a snow blade is determined by one thing, durability. The snow removal industry requires strong and durable equipment. Moving snow is abusive to equipment, and it is essential to have an attachment that can handle it without breaking down at 2 AM. Anything short of this requirement is less than ideal.

Snow contractors need to make money; by design, they make more the faster and more efficient they are. One way they do this is by investing in equipment that will hold up against snow removal. Two things should be considered when looking for a durable plow. These are the material thickness and support flanges.

Material Thickness

Material thickness is a vital component of durability. The thicker the material, the stronger and the longer it will last when plowing snow and ice; having an attachment that can endure the force of running into piles of snow, going over curbs, and hitting unforeseen objects is crucial. The last thing a snow plow operator wants is to be down at 2 AM after a 10-hour shift when it is -12 degrees. Ensuring that your plow is built for the job is one way to prevent downtime, which gets the job done faster. The plow system has three major components to consider: the moldboard, side panels, and the trip edge system.

Moldboard Thickness

The moldboard should be a thick enough material and composition to withstand any abuse in snow removal and retain its shape. The moldboard must be rigid because if it tweaks or bends, it could cause issues for the entire plow system. If the moldboard tweaks, it may shift the attack angle, and suddenly the plow becomes wildly inefficient. KAGE uses 10-gauge (9/64-inch), grade 50 steel on its moldboards, which has proven to hold up over many years. The high-strength, low-alloy steel offers excellent resistance to corrosion. Other snow blades use stainless steel because it is anti corrosive, but is is a more expensive material. It is also more vulnerable to dents and other damage.

Side Panel Thickness

Another critical steel thickness to consider is the side panels. The side panels should be rigid and withstand a lot of impact from all angles. The last thing a snow plow operator wants is to have a bent side panel and accommodate that until he can fix it, which can sometimes take days or weeks in the busy season. Fixing side panels is often a headache that should be much easier to manage. KAGE solved this issue in two ways. It implemented a thicker side panel that is 3/16″ thick when most plows have 1/8″ thick side panels that are welded to the moldboard. KAGE also fixed this by making its side panels bolt onto the frame rather than welding it. This makes the replacement process easy without the headache!

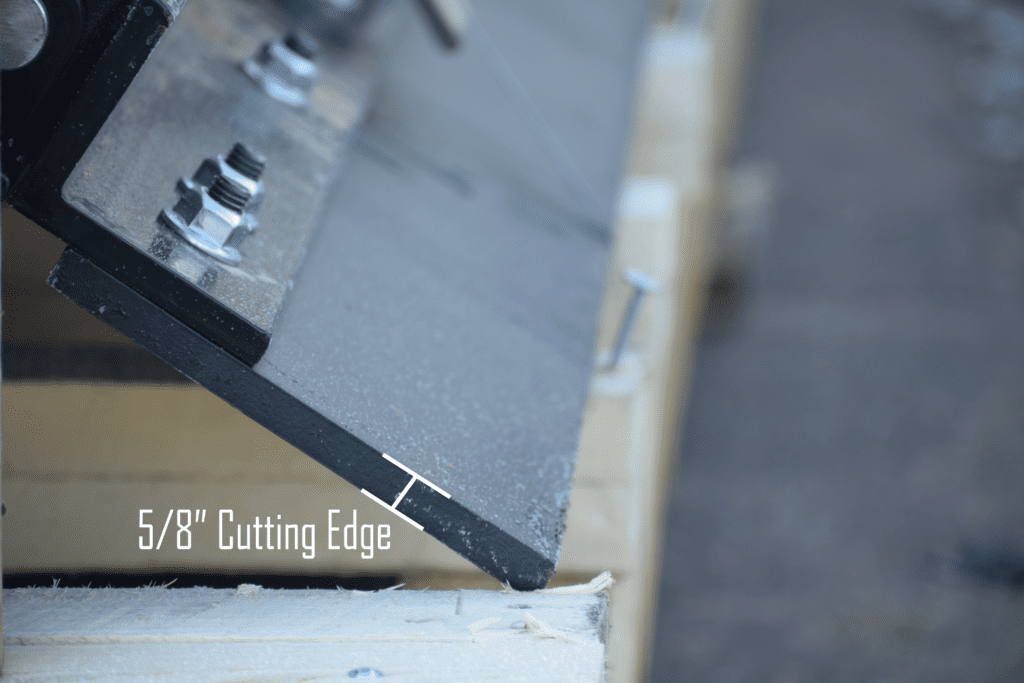

Cutting Edge Thickness

When purchasing a new plow or cutting edge, it is essential to consider the steel composition and thickness. Having the right cutting-edge can improve your efficiency significantly! KAGE uses a 5/8″ thick high carbon steel cutting edge, when most other plows use 3/8″, or 1/2″ thick cutting edges. They are use a grade such as AR-400 with less carbon. The 5/8″ high carbon steel cutting edge improves scraping, by retaining its shape against impact, and the overall longevity of the cutting edge. Some plows comes with a polyurethane edge, because snow does not stick to it and it is more gentle on the substrate. Therefore, KAGE also offers a poly cutting edge so that you can choose what best fits your needs.

Support Flanges

Enough support flanges are vital to keeping your plow up and running correctly. These are necessary for the plow to have strong connection points and are bound to break without many impacts. Snow removal is tough on equipment, even for experienced operators. To ensure your equipment’s longevity, it is essential to ensure that your plow system has reinforcements on the plow and, in specific common wear and breakage points. This improves your overall efficiency, saving you time and money!

Snow Blade Support

The KAGE snow blade is equipped with rib and box form reinforcements. (Left) Other plow systems generally only have rib reinforcements. (Right)

The snow blade, or the moldboard, is a vital component of every plow. Without it, you would not be plowing. Therefore, ensuring that the heart of the snow plow is functional and reliable is essential. Purchasing a plow with designated moldboard reinforcements is a way to save you time and money! KAGE uses a rib and box form construction on the entire back of their moldboard. This ensures that your moldboard is going to remain rigid and functions correctly. To learn more about the KAGE moldboard, check out this video!

Containment Box Support

It is essential that your side panels are thick enough and supported enough to take hard impacts. When purchasing a plow, ensure that your side panels have enough support to keep your equipment up and running. If not, repairs may cost you more time and money than purchasing one with enough support. KAGE systems use enough supports to withstand hard impacts and then some. The KAGE systems have multiple braces to keep the side panels in place, and each of them has fully welded ends with an extra support flange. Through vigorous testing, and multiple broken pieces, we found that the structure we have now held up the best. In our design process, we decided to piggyback common building construction techniques and implement a triangle shape to our supports to ensure its rigidity. We include supports on the top and bottom of each side panel following this technique.

The KAGE System

The KAGE system is a 2-in-1 angle snow blade and containment box that allows you to switch from pushing and windrowing in seconds. We designed this system for a series of equipment. We built one for skid steers, small and large tractors, compact and large wheel loaders, and telehandlers. This system is overbuilt by design and reinforced to maximize efficiency and minimize downtime! The KAGE system has improved our customer’s efficiency by 30-50%. This is not only because of the engineered 2-in-1 system but because each support was thoroughly thought through to ensure that the KAGE system will last. To learn more about the KAGE 2-in-1 systems and the other products we offer, check out our YouTube channel!

Learn more about saving time and money with the KAGE system at www.kageinnovation.com. You can visit our contact us page if you’d like to talk to a sales representative about the product. To purchase a product, visit our shopping cart or place an order on the phone. Check out the Kage YouTube channel to watch videos about our products!

Recent Comments