When you need to move a lot of snow in a hurry, snow pushers are the best form of snow plow out there. What sets a snow pusher apart from straight snow blades are the side panels, designed to contain the snow in front of the plow and prevent dribbling or spilling of snow off the sides of the blade.

With side panels also comes challenges – especially if the sides of the “snow box” are fixed in place. Among those challenges are:

- keeping your blade and box at the proper angle for scraping

- preventing sections of the blade from digging into the substrate

- maintaining proper traction for the machine for optimal handling

- & preventing excess down pressure.

Float is essential for combatting those challenges by allowing the plow to contour to different surfaces without the plow operator having to make adjustments on the fly. This reduces fatigue on both the operator and the snow pusher – especially in challenging terrains. While some machines offer a float function, many do not – and all can benefit from float being built into the pusher itself. (Offer float in a snow pusher intended for wheel loaders is especially important as it helps keep, the front wheels in contact with the ground for steering.)

Snow Pusher Float Mechanisms

Different types of float mechanisms may be incorporated into snow pushers to achieve this flexibility, including:

- Floating attachment plates/couplers

- Floating skids

- Floating cam locks

- Floating cutting edges

- Floating moldboards

- Oscillation/articulation

- Hydraulic float systems

- Spring loaded trip edges

- Box Float

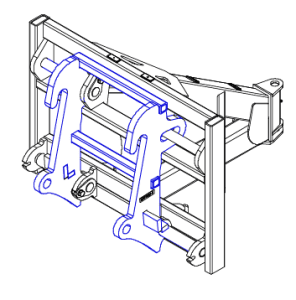

Floating attachment plates & couplers

Floating Skids

Floating Cam Locks

Floating Cutting Edge

Floating Moldboards

Oscillating/Articulating Moldboards

Hydraulic Float Systems

Hydraulic float involves using pressurized fluids to allow the blade/box to follow contours. This means hoses and controls will be involved, leaving more opportunities for breakages. However, it does give you more control of how and when the float occurs.

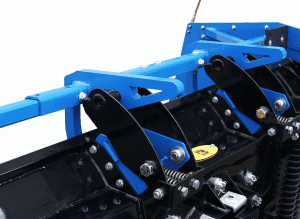

Spring loaded trip edges

Remember to check the specific models and product specifications from each manufacturer to confirm whether a particular snow pusher includes float features. The specific type of float mechanism can vary between different snow pusher models and manufacturers. The choice of float features often depends on factors such as the intended use, the type of terrain, and the preferences of the operator. When considering a snow pusher with float capabilities, it’s essential to understand the specific float features incorporated into the design and how they contribute to the overall performance of the equipment.

Box Float

All of KAGE’s 2-in-1 systems offer a certain degree of float in the boxes – even without floating cam locks. This is achieved by allowing additional space at the point where the box connects to the blade. In the SnowFire system, there is wiggle room in the cam lock itself, that allows the box to swing, pivot or lift slighty to accommodate surfaces that aren’t perfectly level. In the SnowStorm System, the hyro clamps lock somewhat loosely around a bar or pipe to allow for some float. In the SnowDozer, the hydro lock pins on the moldboard extend into a reinforced and oversized hole in the side panel of the box to allow limited movement from the box.

KAGE Floating Snow Pushers

KAGE Innovation offers the following snow pushers with the following float mechanisms.

-

SnowFire Plow & Pusher System

- Oscillation

- Spring Loaded Trip Edge

- Floating Skids (upgrade option)

- Floating Cam Locks (upgrade option)

- Floating Cutting Edge (upgrade option)

- Box Float

-

SnowFire Blast Snow Pusher

- Floating attachment plate

- Oscillation

- Spring Loaded Trip Edge

- Floating Skids

- Floating Cutting Edge (upgrade option)

- Box Float

-

SnowStorm Plow & Pusher System

- Floating coupler

- Oscillation

- Spring Loaded Trip Edge

- Floating Cutting Edge (upgrade option)

- Box Float

-

SnowDozer Plow & Pusher System

- Floating Coupler

- Oscillation

- Spring Loaded Trip Edge

- Floating Cutting Edge (upgrade option)

- Box Float

Recent Comments